Production

Insourcing instead of outsourcing.

Production of the manufacturing tools, production of CONNEX tensioning elements, warehousing, thorough final inspections: we do as much as possible in-house so that we can guarantee optimum quality at every stage. Take a look at some of our production facilities to see how it's done.

The benefits of in-house production

Fast-tracked prototype production

Your idea is brought to life immediately – your product is brought to market without delay.

Unbeatable flexibility

We are big enough to be able to manufacture and deliver large-scale orders. And small enough that we can respond proactively to customer needs.

Consistent CONNEX quality

Since we make everything in-house, we can "go beyond the norm" at every step of the way – in ensuring product quality, managing deadlines and logistics, and offering a personalised service.

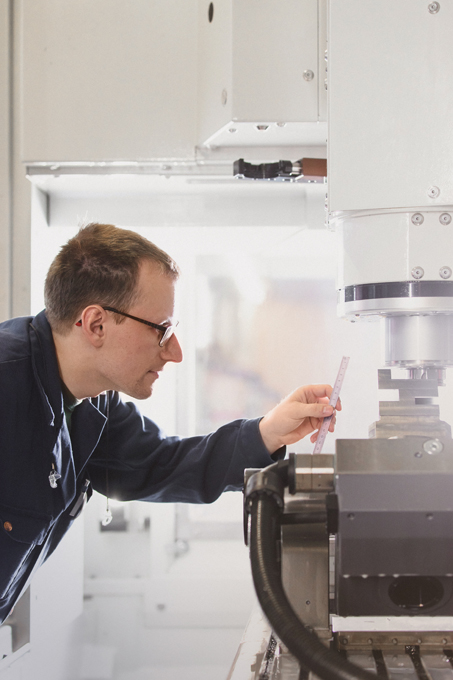

In-house tool making

We prefer in-house.

Instead of relying on global supply chains, we prefer to create as much value as possible right here. A prime example of this is the tools that we use. We design and manufacture them entirely in-house at CONNEX, as well as using the experience gained in our day-to-day production activities to constantly refine them.

Storing raw materials in-house

Always ready for production and delivery.

A compact mobile rack warehouse for coils and sheets; lifts and paternoster systems for finished goods: when you look at these systems, one thing is clear. CONNEX does not see warehousing as a burdensome cost factor, but rather as a vital part of its success. This enables us to guarantee optimum availability and act fast, for instance in order to start working on prototypes right away.

Perfected processes

Experienced teams, sophisticated processes.

For years, CONNEX tensioning elements have successfully showcased the benefits of their underlying principle. Throughout this time, we have been drawing on our innovative strength and the wealth of experience gained by our long-serving employees in order to make continuous refinements and improvements to our production methods.

In-house heat treatment

The independent experts.

Nothing is too hot to handle for our in-house production team – even complex heat treatment. We have our very own specialists and a range of modern, automated equipment.

Integrated management system

For long-term success.

We have a comprehensive grasp of management principles. Through pre-emptive actions and constant refinement of our processes, products, methods and relationships, we deliver the best for our customers and employees. The CONNEX management system is an effective tool that enables us to keep a complete overview and take a systematic approach:

Cutting-edge testing methods

Quality you can rely on.

The reliability of our products goes well beyond the norm. And we guarantee this by putting our products through a battery of tests, some of which are conducted in our modern laboratory for metallurgical testing. Even our test methods themselves are examined on a regular basis so that we can keep them up to date with the latest technological developments.